Promat Academy

Cardboard packaging, which is encountered in almost every aspect of our daily life, has become an essential element of modern life. With its lightweight and easily moldable structure, cardboard packaging stands out. Thanks to its durability and recyclable properties, cardboard packaging emerges as an eco-friendly alternative. Used in a wide range of products from food to electronic devices, pharmaceuticals to personal care products, cardboard packaging ensures that products reach consumers fresh and safely. Additionally, its printing and design flexibility provides unique advertising and promotional opportunities for brands.

Folding Types

In the design and production process of cardboard packaging, various folding techniques are applied to meet different needs and usage areas. These techniques enhance the functionality of the packaging, ensuring the protection and shelf life of the product. They also increase efficiency in the assembly and packaging processes, ultimately reducing costs.

Knife Scores

The specialized cutting knives used in the production process of packaging cardboards are used to shape the cardboard according to a specific design. These knives enable the cardboard to be cut in the required places or scored for folding. The knife marks allow for the assembly of the cardboard and easy assembly by the end user.

The Importance of Knife Marks in the Production Process

The knife marks accurately guide the assembly and folding of the package. This increases the safety of the product in the package and improves the user experience. It also has a significant impact on the aesthetic appearance of the packaging. Correct cuts and slits make the packaging look neat and professional.

Printing Types and Techniques

⦁ Offset Printing: Ideal for high-quality and high-volume printing jobs, offset printing is preferred for color consistency and clarity. Using the CMYK color model, detailed graphics and text can be printed on almost any type of cardboard surface.

⦁ Flexo Printing (Flexible Relief Printing): Flexo printing, a type of printing developed for flexible materials, uses fast-drying inks and is often the preferred method in cardboard packaging production. It is suitable for simple graphics and large volume orders.

⦁ Digital Printing: Suitable for small printing jobs, digital printing is a fast and cost-effective solution. High-resolution prints can be produced quickly, making it ideal for personalized designs.

⦁ Lithographic Printing: Used to produce detailed graphics and photo-quality prints, lithographic printing is suitable for packaging that requires high image quality.

⦁ Screen Printing: This printing method, which uses a thick ink layer, allows for more vibrant and vivid colors. It can create effective prints on both flat and irregular surfaces.”

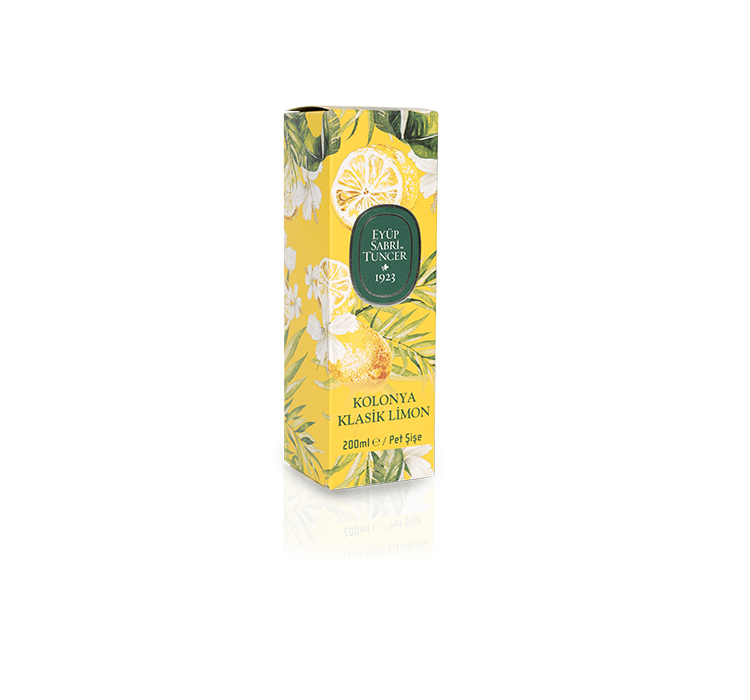

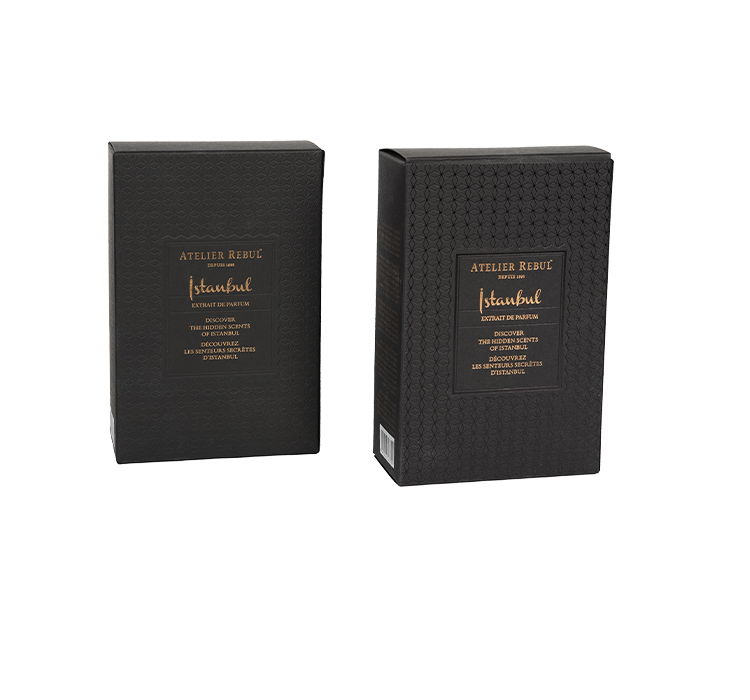

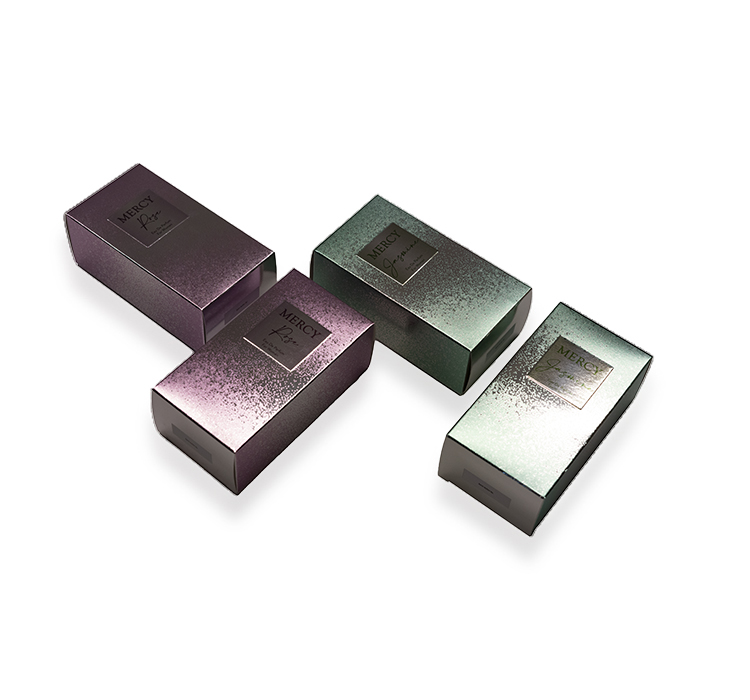

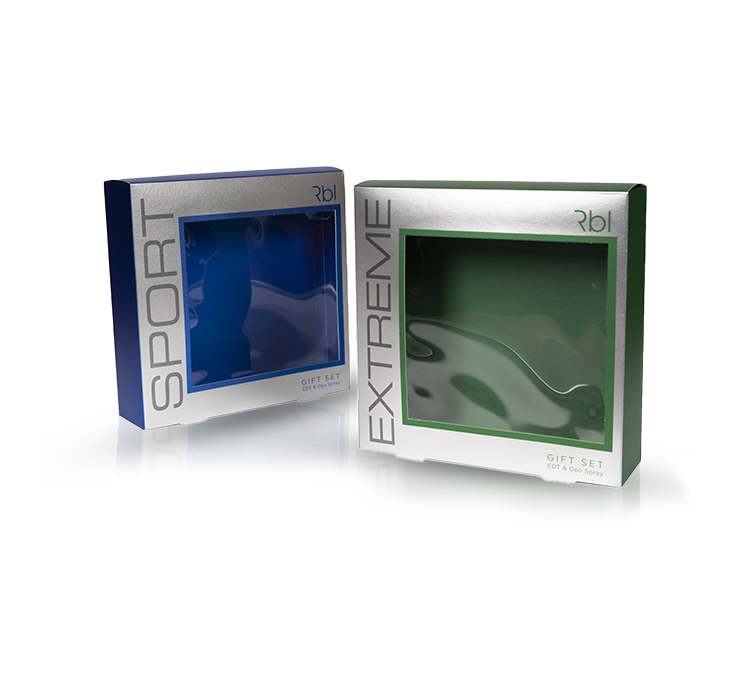

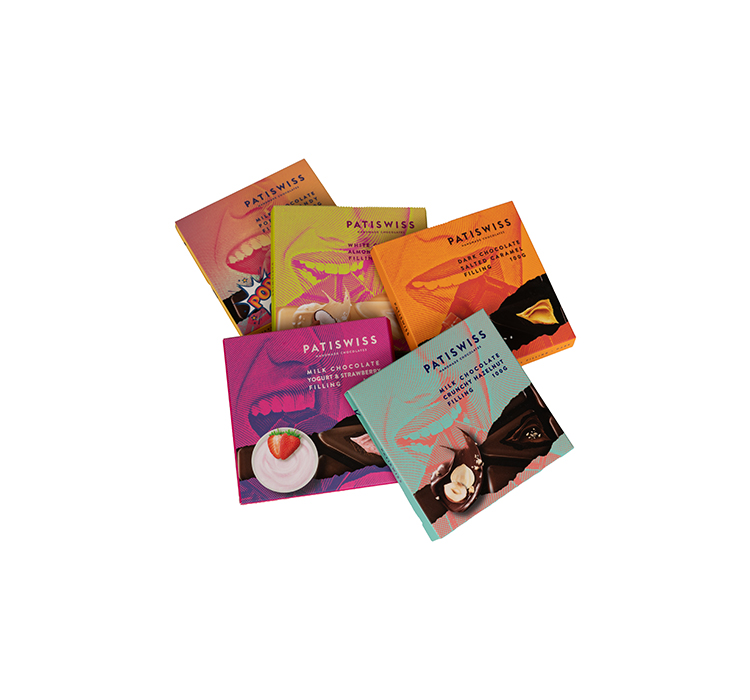

Cosmetics

We understand that a well-designed and quality-crafted package creates the perception of a safe and high-quality product among consumers. We are also aware of how influential this perception can be in a consumer’s decision to purchase a product. Therefore, we offer a range of special printing effects, cutting and folding techniques, gold/silver metallization, hot foil applications, effect varnishes, and much more to ensure that your packaging stands out. With our state-of-the-art machinery and skilled personnel, we can easily provide these enhancements.

Furthermore, if you are not satisfied with your current product’s packaging, we can make the necessary improvements. Additionally, if you have a brand new product, our R&D team can offer you packaging mock-ups that are tailored to your product and closely match the design you envision.

While doing all of this, we are mindful of our responsibility to the environment. We carefully select raw materials and use them responsibly. In cases where guidance is needed, we are here to assist you.

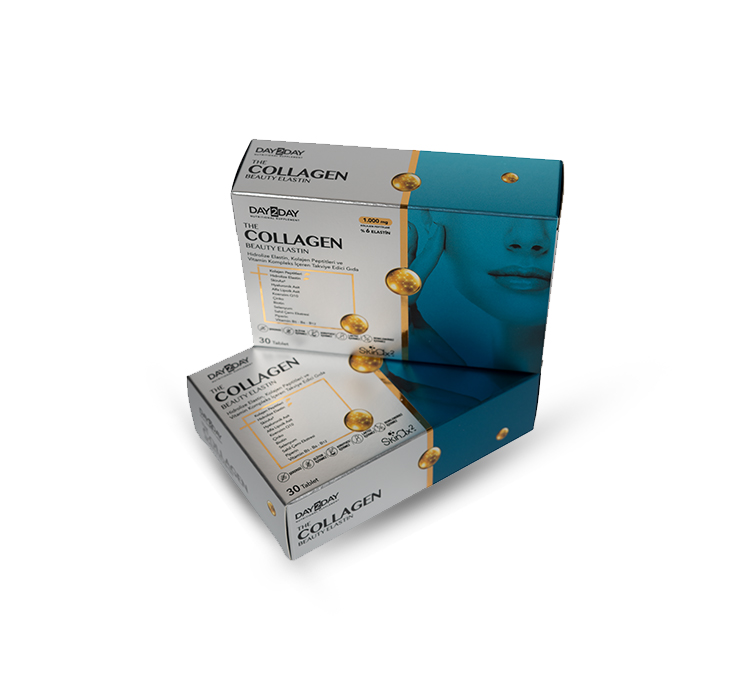

Food Supplements and Medical

We are aware that a well-designed and high-quality packaging creates the perception among consumers that the product is safe and of high quality. We also understand how influential this perception can be in a consumer’s decision to purchase a product.

To ensure that your packaging grabs attention, we offer a wide range of special printing effects, cutting-folding-gluing techniques, gold/silver metallization, hot foil applications, effect varnishes, and much more. With our robust machinery and skilled personnel, we can easily provide these enhancements.

Additionally, if you are not satisfied with your current product’s packaging, we make the necessary improvements. Moreover, if you have a brand new product, our R&D team offers packaging mock-ups that are tailored to your product and closely match the design you envision.

Throughout all of this, we are mindful of our responsibility to the environment. We pay close attention to our choice of raw materials and their usage, and we provide guidance when necessary

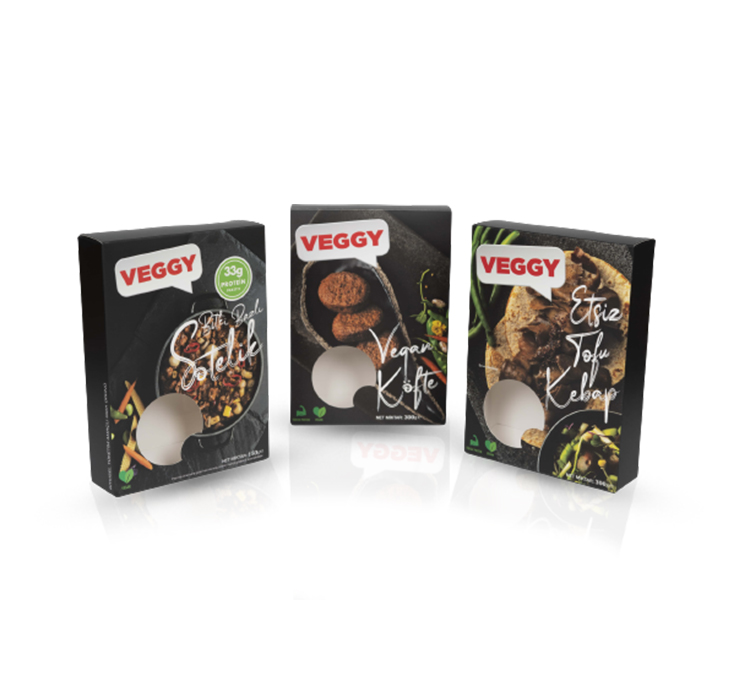

Food

We are aware that a well-designed, environmentally friendly, and meticulously crafted packaging creates the perception among consumers that the product is safe and of high quality.

We have a strong machine lineup to meet your expectations by using food-grade paper, food dyes, and food-safe varnishes, among other applications, to make your packaging suitable for your product. For products sold on shelves or in cold storage areas, we provide recommendations tailored to your needs and can easily provide services to differentiate your packaging with cutting, folding, gluing techniques, hot foil, and more.

If you are not satisfied with your current product’s packaging, we make the necessary improvements. Moreover, if you have a brand new product, our R&D team offers packaging mockups that are tailored to your product and as close as possible to the shape and design you envision.

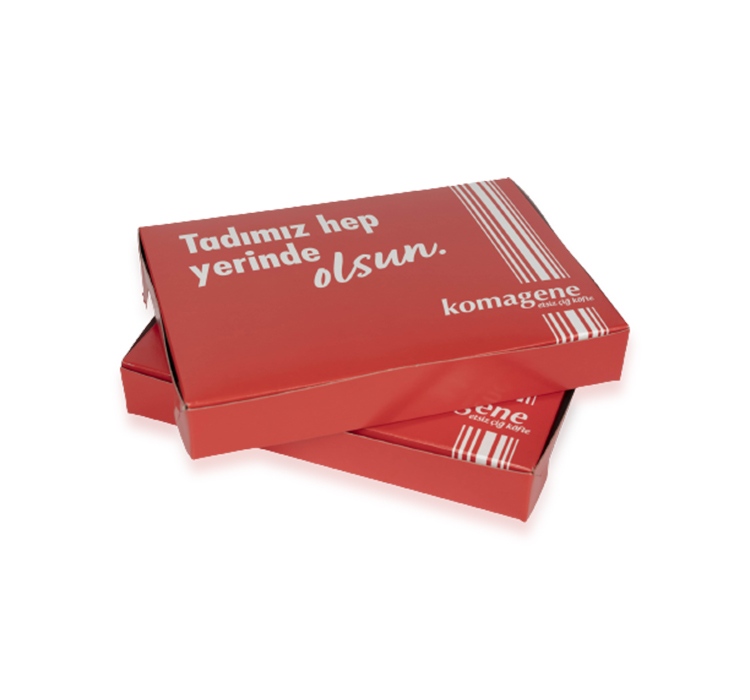

Other

In addition to the sectors mentioned above, we also provide cardboard packaging services to many other sectors both domestically and internationally, including fast food (take away), textiles, stationery, toys, FMCG, chemicals, cleaning, defense industry, and many more.

We can easily ensure that your packaging stands out with special printing effects, cutting-folding-gluing techniques, gold/silver metallization, hot foil applications, effect varnishes, and much more, thanks to our strong machinery lineup and experienced personnel. If you are not satisfied with your current product’s packaging, we make the necessary improvements. Moreover, if you have a brand new product, our R&D team offers packaging mockups that are tailored to your product and as close as possible to the shape and design you envision.